Safety Nets Solutions

Fall protection systems are essential to protect people working at height. Falls are the leading cause of fatalities in construction, accounting for about one-third of all fatalities in the industry. Each worker exposed to an open edge (or a leading-edge) where the risk of fall may cause an injury must be protected and that is why our fall arrest system is designed for. Consideration and priority must be given to collective and passive fall prevention systems for the selection of fall protection equipment when working at height.

TSS fall prevention and protection systems are designed to drive the industry safety and construction safety standards forward in UAE and the Middle East. We pride ourselves on having in-depth industry and market knowledge and understanding the need of our customers.

Looking for reliable safety net systems to secure construction zones and high-rise projects? Our Safety Nets Solutions provide robust fall-protection coverage, compliance with industry standards, and tailored service support — perfect for construction sites, building envelopes, and maintenance applications.

Safety Net Fans

Adaptive safety net fan that absorbs fall energy and fits complex façades, ensuring reliable high-rise protection.

Vertifan Protection Screen

Evolved safety net fan is essential, delivering stronger protection and notable performance gains

Safety Nets

Safety nets lessen fall impact, protect workers at all levels, and meet all rigorous European safety regulations.

TSS Vertical Nets

TSS installs vertical safety nets meeting EN 13374 and EN 1263-1, delivering certified temporary edge protection

Drone Attack Netting

Safety nets for construction sites

When operating on active construction sites, worker safety and material containment are key. Our safety nets are designed for rapid deployment across beams, scaffolding, roof edges and perimeter zones.

Key benefits include:

- Minimised risk of falling objects reaching lower levels

- Enhanced worker confidence and site productivity

- Adaptability to irregular site geometry

Types of safety net in construction

From standard polypropylene nets to heavy-duty steel-mesh systems, safety nets vary based on application. Common types include:

- Perimeter nets for façade and roof edge protection

- Under-deck nets for suspended slab work

- Material-containment nets to prevent debris falling

- Custom knockout zones based on project specifics

Fall protection safety net

In high-risk areas where ladders or harnesses alone are insufficient, a fall-protection safety net offers an additional layer of security. Typical installation factors to assess:

- Mesh size and load-bearing capacity

- Anchor point strength and spacing

- Impact energy absorption rating

Benefits of Safety Nets in Construction

Using high-quality safety nets leads to improved site safety culture and reduced incident rates:

- Reduced lost-time incidents from objects or personnel falls

- Compliance with local regulations and insurance requirements

- Enhanced site reputation and fewer delays due to safety stoppages

Building Safety Net Solutions

Whether you’re working on a new skyscraper or retrofitting an existing structure, building safety net solutions are tailored to façade, roof, and atrium applications. Features to look for:

- UV-resistant materials for long-term exposure

- Adjustable modular frames for phased works

- Quick-release mechanisms for emergency access

Construction Safety Net Services

Delivery of the safety net system is just the beginning: our service provision covers installation, inspection, and maintenance.

Maintenance checklist:

- Weekly visual checks for mesh damage or sagging

- Monthly tension tests on anchor points

Annual full structural review and recertification

Safety Net Installation & Maintenance Process

- Site survey and risk-mapping of potential fall/containment zones

- Selection of appropriate net material and anchorage system

- Installation by certified technicians according to manufacturer specs

- Record-keeping of load-testing results and inspection logs

- Scheduled maintenance and replacements as needed

Standards and Certifications (EN 1263 / EN 13374)

It’s vital to select systems certified under recognised standards:

- EN 1263 – specifies safety nets for accessory protection and personnel safety

- EN 13374 – outlines temporary edge protection systems

Our nets meet or exceed these benchmarks to ensure you stay fully compliant and audit-ready.

Safety Net Applications in High-Rise Buildings

High-rise environments pose unique challenges: wind load, height differential, emergency evacuations. Here’s how safety nets help:

- Provide perimeter fall-protection during façade works

- Capture falling tools or materials from high levels

- Enable safe debris containment when multiple levels are open simultaneously

Safety Net Services Across the Middle East

Our comprehensive Safety Net Solutions are now available across key Middle Eastern markets — including the UAE, Saudi Arabia, Kuwait, Bahrain, Oman, and Qatar.

We provide end-to-end services covering design, supply, installation, and maintenance of certified fall-protection systems tailored to regional construction standards and climatic conditions.

FAQ

What is a Safety net fan?

Safety Net Fan is a system comprising of safety nets used in conjunction with a metal frame used to prevent the fall of people or materials from an open edge.

Safety net fans are designed and tested to EN1263-1 Type T. The safety netting element may be made up of multi-layers with varying mesh sizes to catch small objects and debris. The main safety net element must have a 20KN border rope around the perimeter of the nets.

What are the features of TSS Safety net fan?

• Double-layer nets made up of 60×60 and 20×20 nets manufactured from high tenacity polypropylene (HTPP) material with an optional light-duty Debris net as the third layer.

• UV Treatment to resist sun damage.

• 3.1m Standard width or 4.7m Extra Wide widths.

• Resistant to high wind loads, able to be tied top/ bottom against overturning

• 0.85m overlap between units providing more protection between units.

• Full range of accessories to enable connection to various types and shapes of structures.

• Manufactured from Steel (Hot Dip Galvanized finish) and Patented Extruded

Aluminum profiles to provide optimum strength and weight.

What are the applicable European standrads for Safety net fan?

In Europe Safety Nets must be designed and manufactured to EN1263-1:2014 Type T. This involves the dropping of a 100kg spherical test mass twice from a 7m height in the most unfavorable location. The test mass shall be held by the system and the test mass must not touch any elements of the metal supporting framework. Permanent deflection is allowed.

Safety Net Fans are installed on-site by EN1263-2:2014 in terms of position with the level where the risk of fall may occur.

The safety nets used in Safety Net Fans must be manufactured in compliance with EN1263-1:2014. This standard defines the mesh size and thickness (energy absorption capacity), designation, border finish and rope, tensile strength of each component used, labeling and annual inspection regime for safety nets.

What are the applicable American standrads for Safety net fan?

in America ANSI A10.37-2016 covers Debris Net systems used during Construction and Demolition operations. This type of net and its metal structure is designed, tested and installed to catch or contain debris only. The testing and use is in accordance with the manufacturers qualification test. ANSI A10.37-2016 covers the mesh size, net selection, marking, installation, maintenance and on-the-job testing.

ANSI A10.11-2010(R2016) covers Safety Requirements for Personnel Nets.

This standard establishes safety requirements for the selection, installation and use of personnel nets during construction, repair and demolition operations.

The purpose of this standard is to provide minimum design, testing and use requirements for personnel nets.

Determining the positioning the Safety net fan?

If a person trips when they are moving forward, they fall forward as well as downward. The distance they fall forward is affected by the height of the fall; that is, the higher the fall, the further the forward movement. Nets providing protection at the edge of a work platform must be wide enough to include the falling person’s forward movement. The width of the net between the edge of the work platform and the outer edge of the safety net is called the catching width.

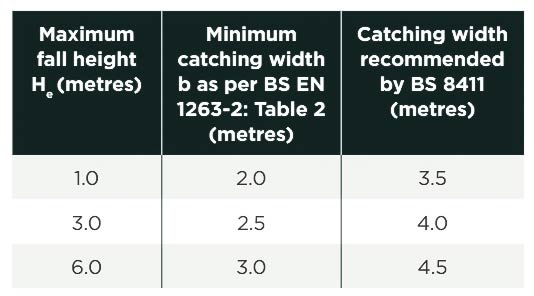

BS EN 1263-2: sets out minimum catching widths for maximum fall heights. As an added safety factor, BS 8411 recommends extending the net at least 1.5 meters beyond the distances given in Table 2 of BS EN 1263-2.

What is the difference between a safety net and a safety harness?

A safety harness protects an individual directly by restraining or arresting a fall, whereas a safety net catches falling personnel or objects after the fall occurs. Nets offer collective protection over a work zone, especially where multiple workers are exposed.

How often should safety nets be inspected?

Weekly visual inspections are recommended, monthly tension/load tests, and annual full structural reviews by qualified personnel to ensure mesh integrity, anchorage stability and compliance with manufacturer recommendations.

Are safety nets reusable across different projects?

Yes — provided they are certified, undamaged and re-installed according to spec. Factors such as UV exposure, abrasion or damage reduce service life; always review certification and condition before reuse.

Do safety nets need to meet specific regional standards?

Absolutely — in many jurisdictions you’ll need compliance with EN 1263 (for nets) or EN 13374 (for edge protections), or the local equivalent. Using certified systems helps ensure regulatory safety and insurance acceptance

Are your safety net services available across the Middle East?

Yes, we operate across the UAE, Saudi Arabia, Kuwait, Bahrain, Oman, and Qatar, offering certified safety net design, supply, and installation. All systems meet EN 1263 and EN 13374 standards and are built for the region’s heat and UV conditions.